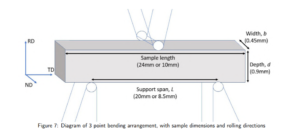

Three-point flexural testing (or three-point bending) is a mechanical testing technique in which a cuboidal sample of a material is suspended on two support pins, and bent by lowering a third pin through its centre. The force required to lower the pin and bend the sample is recorded, and this data can be used to calculate a flexural stress-strain response for the material. This can then be used to analyse the deformation and fracture properties of the material, and compare it to other materials.

In four-point bending, two central pins are lowered to bend the sample. This creates a larger region of the sample that is maximally stressed, providing more reliable results.

Usually, mechanical tests require relatively large samples. This is not always a feasible option for expensive or exotic alloys that we may only produce in small quantities. Sub-scale three-point bending is suited towards samples as small as 12mm long and 1mm thick, and is ideal for analysing materials with limited volume.

Figures

Figure One: Three point bending (Heymer, 2020)